The Big Guide to Sustainable Aviation Fuel

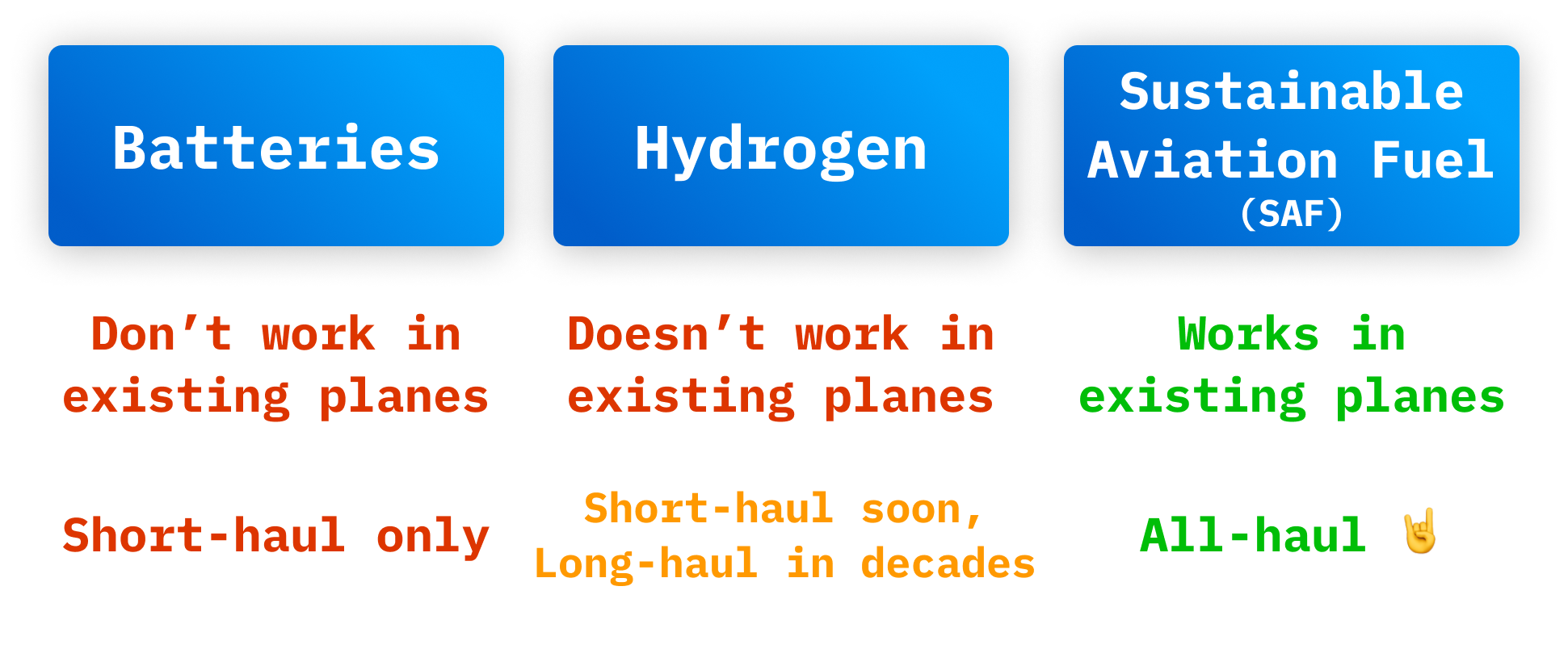

There are three ways to decarbonise flying.

The world's existing fleet of planes is huge, and can only run on jet fuel.

Therefore, we need a drop-in fuel replacement that doesn’t cause warming. This is called Sustainable Aviation Fuel (SAF).

This piece is a concentrated onboarding guide to SAF. We'll walk through the different methods for making SAF, and explain what's tricky and exciting. No chemistry knowledge is assumed!

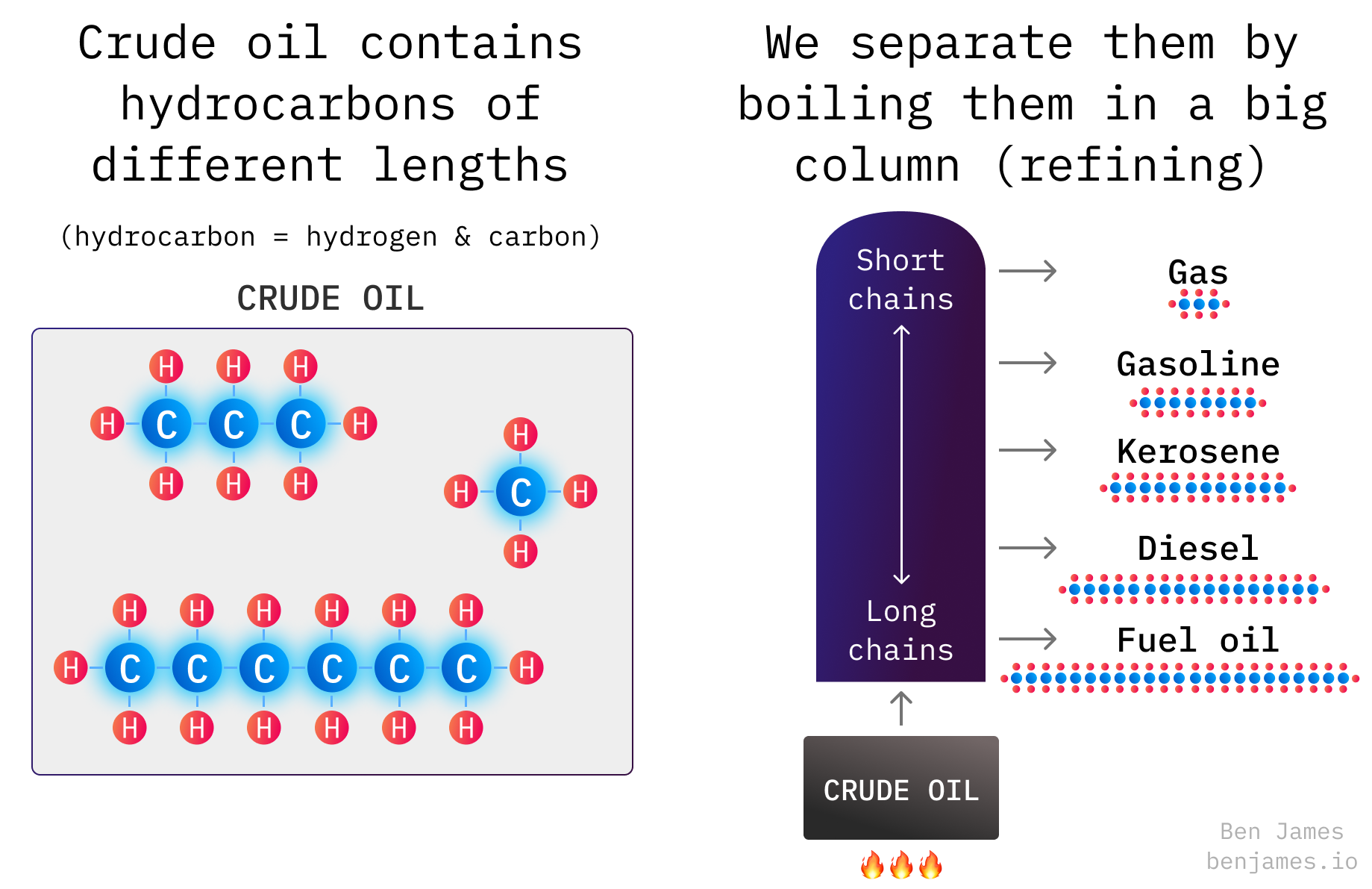

Jet Fuel 101

Firstly, we need to know our enemy. What is SAF trying to replace?

Jet fuel is just kerosene, which is a mix of medium-length hydrocarbons. But wtf does that even mean?

The aim of SAF is to make a fuel that’s chemically identical to kerosene. We want a drop-in replacement.

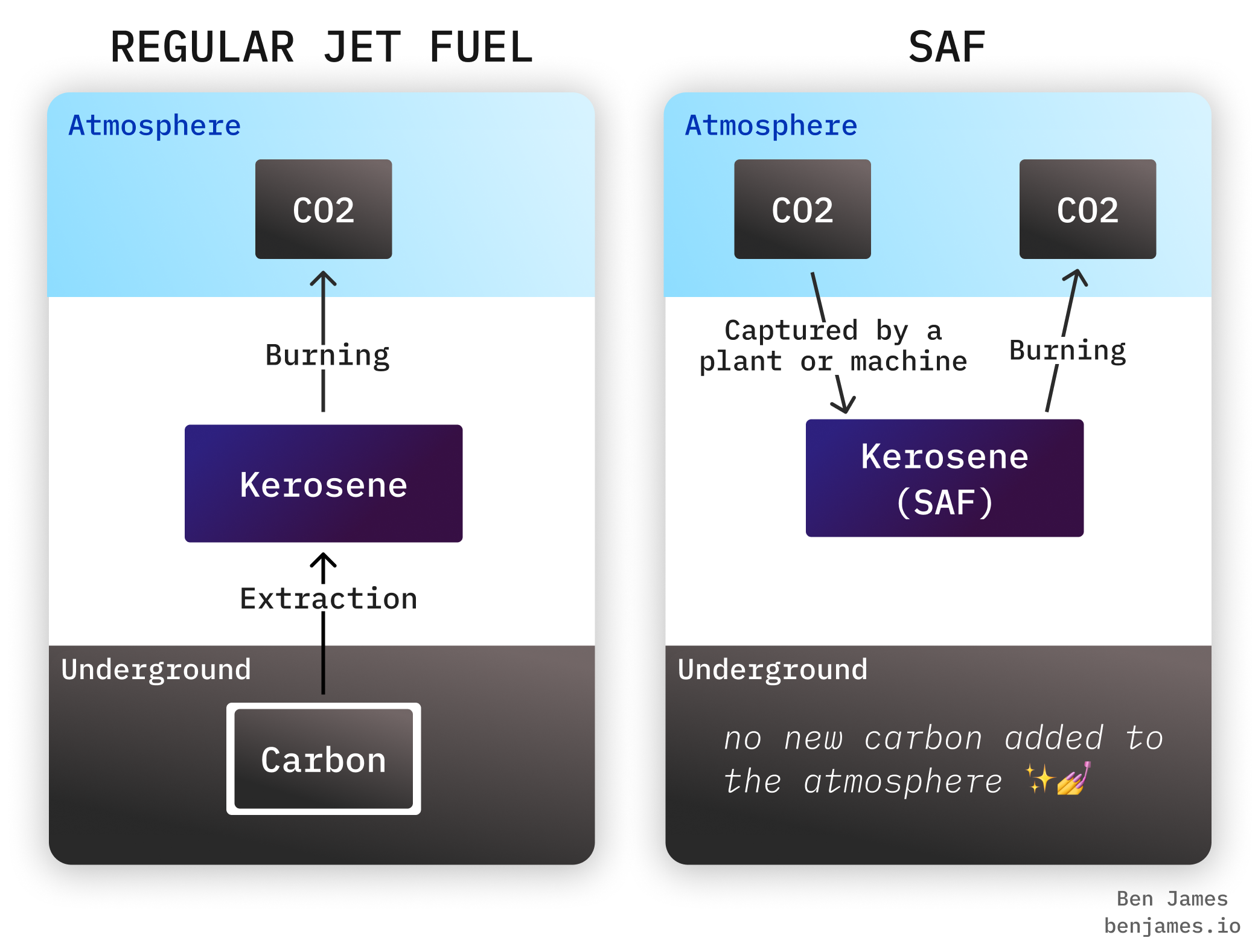

That's confusing, because it means that burning SAF emits just as much CO2 as burning regular kerosene. The difference is where the carbon in the fuel originates from.

CO2 is not the biggest problem here

There’s another twist.

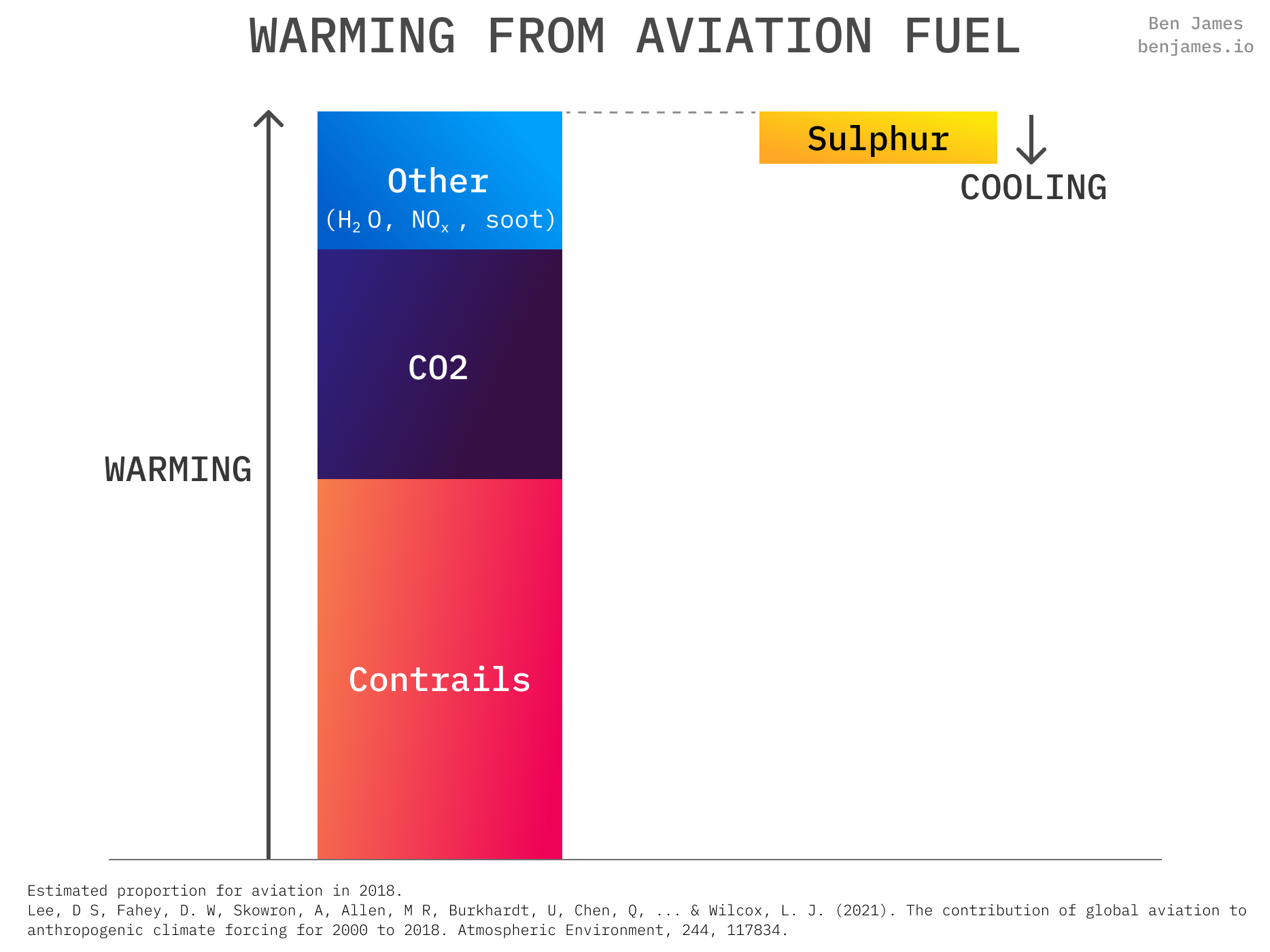

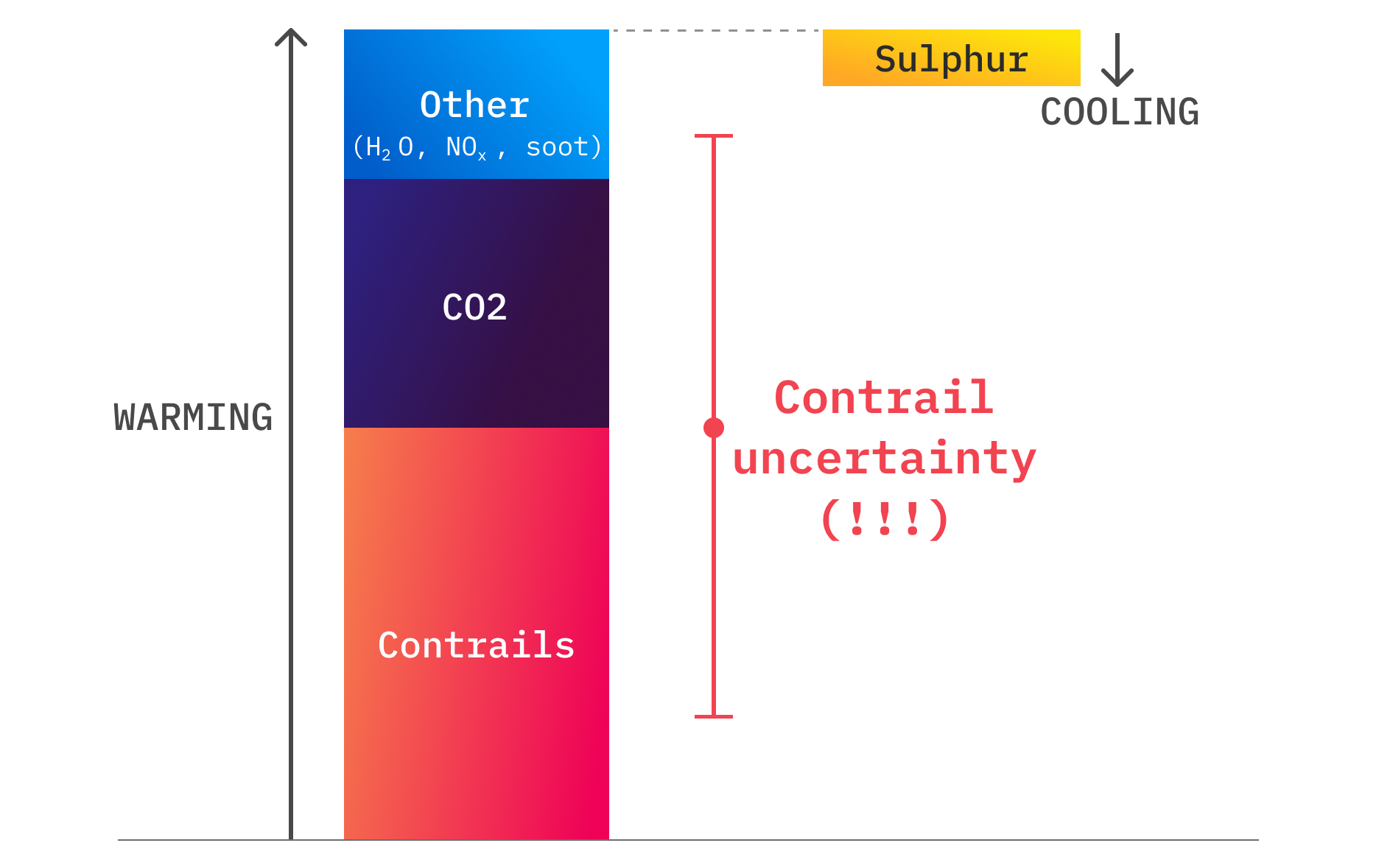

Aviation’s biggest warming effect does not come from CO2. It comes from contrails.

Here’s the warming breakdown:

The crazy part is that we know very little about contrails, and the warming that they cause. It’s an active research area, but our uncertainty is massive.

One big benefit of SAF is that it causes less contrails. This is because fossil kerosene contains compounds called aromatics, which produce soot when burned. That soot causes ice to form in the air, because it provides a place for water vapour to crystallise.

SAF contains less aromatics, which means that it burns cleaner and forms less contrails [footnote 1].

Planes don’t always make contrails - they’re only created when flying through humid regions.

If we have good predictions of meteorological conditions, we can optimise flight paths to minimise contrails.

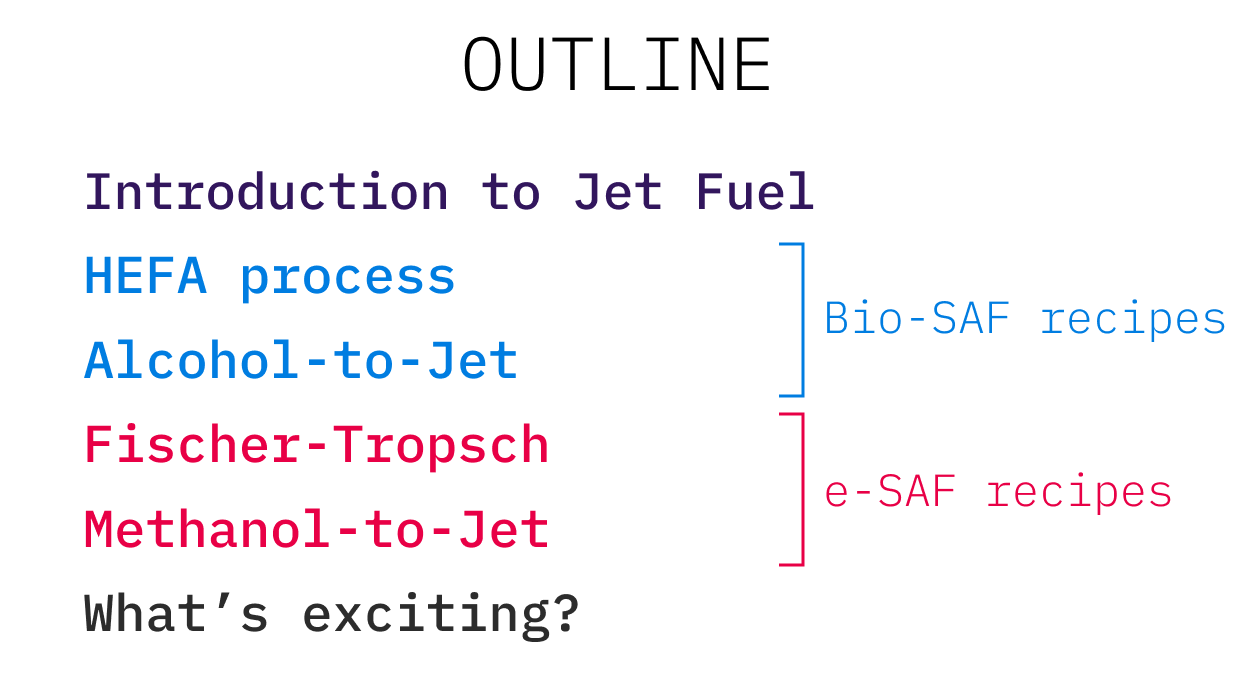

How to chef up some SAF

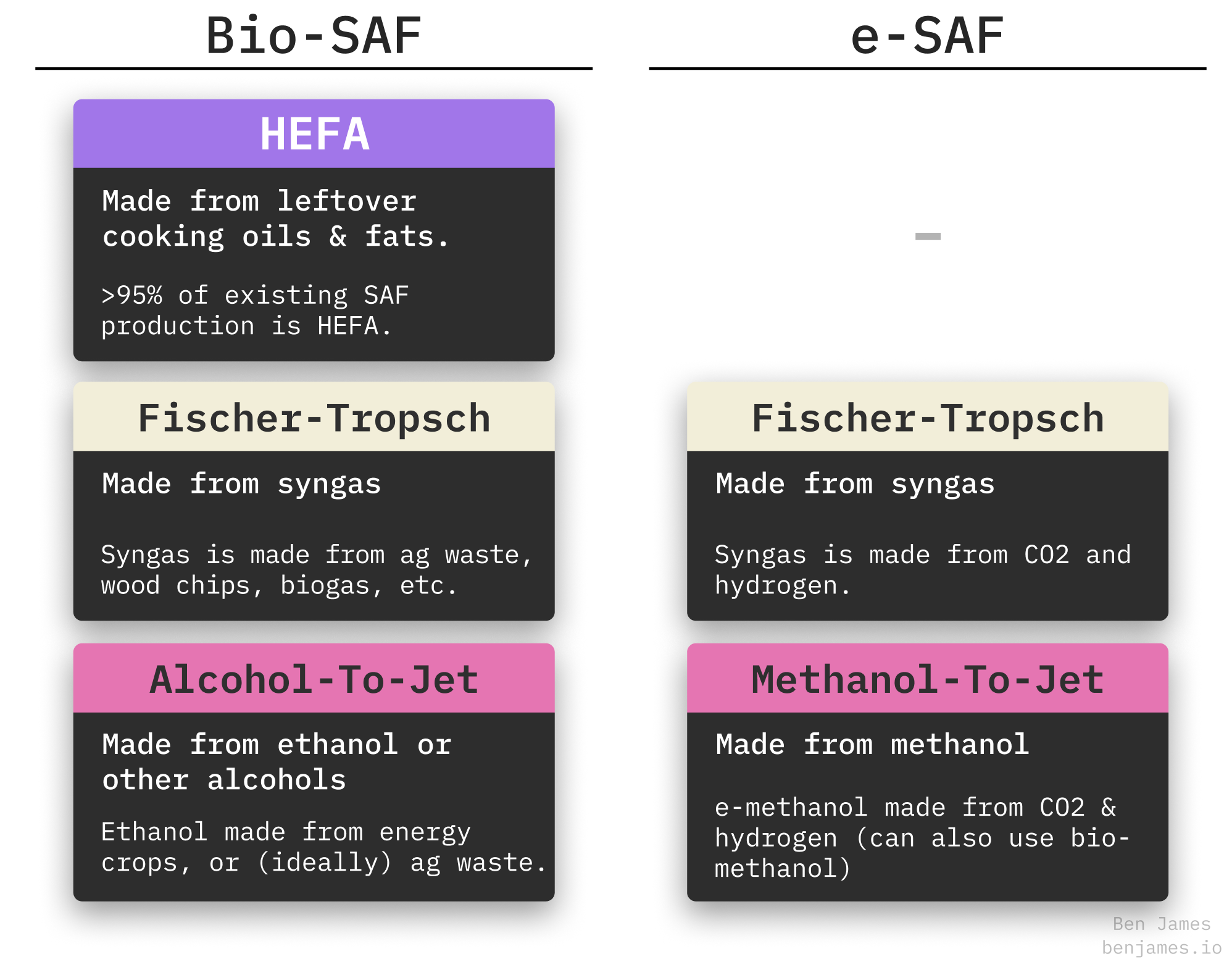

There are two types of SAF: Bio-SAF and e-SAF. This is because there are two ways to source carbon: using a plant, or using a machine.

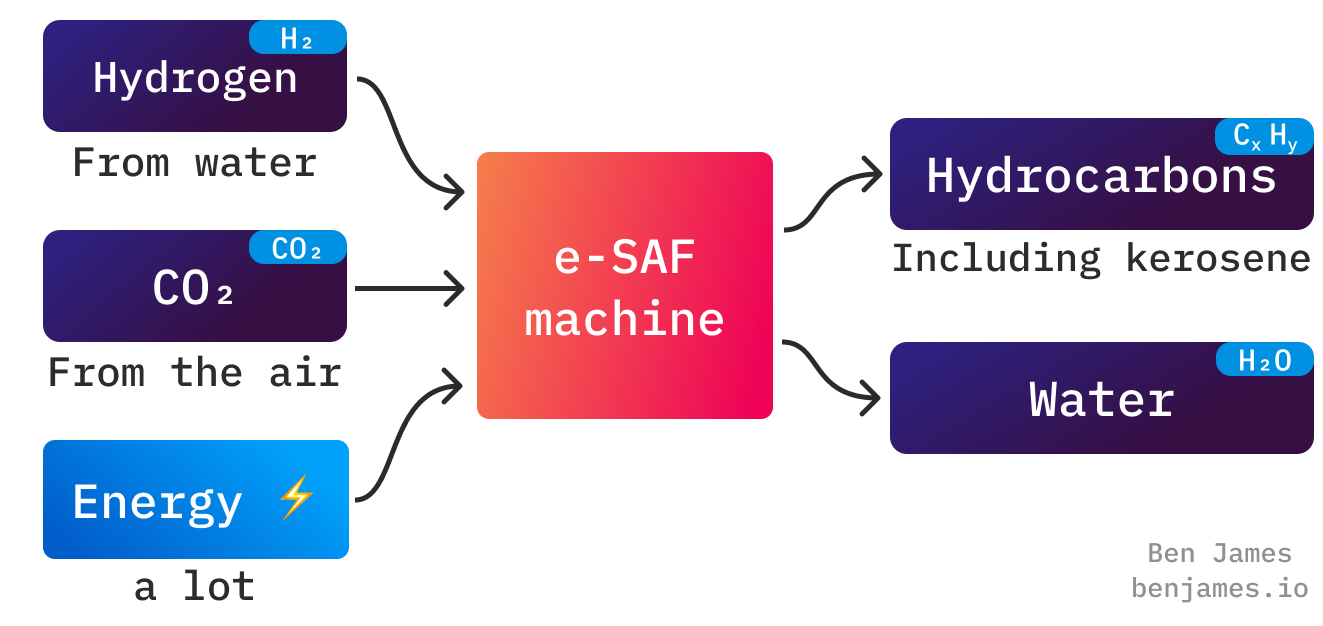

If you use carbon that was captured by a machine, you are making e-SAF. Sometimes it’s called e-kerosene, synthetic fuel, or electrofuel, because you need electricity to make the main ingredients.

Unfortunately, we need a lot of plants to make Bio-SAF, or a lot of energy to make e-SAF. This is probably the most important point in the guide:

This is why only 0.2% of all jet fuel today is SAF.

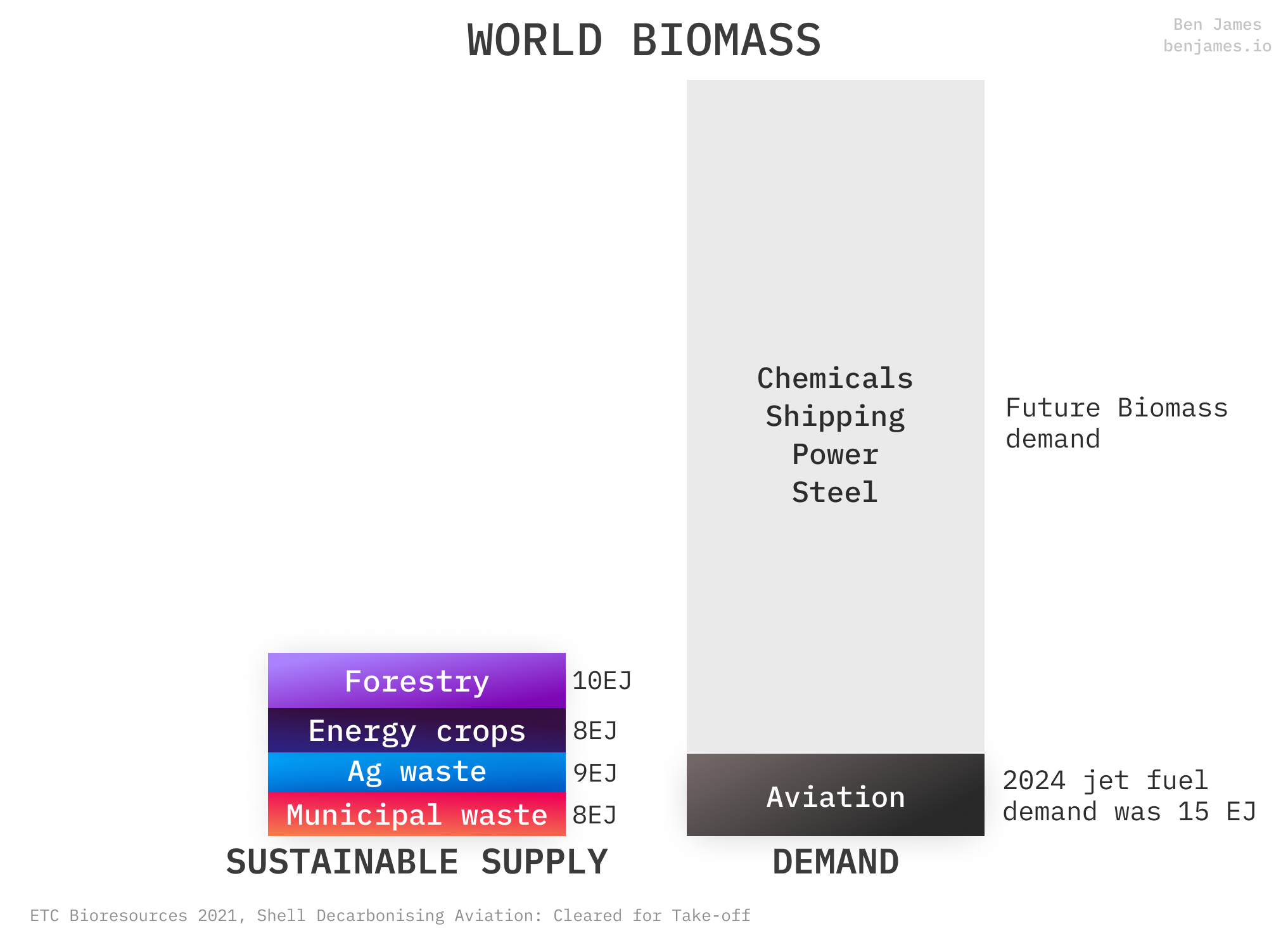

Biomass supply:

The world has a limited supply of sustainable biomass. If you are in the business of producing Bio-SAF, your quest is roaming the earth, desperately searching for enough plants/oils/trees to feed the loud sucking sound emanating from your bio-SAF production plant.

If we replaced all of today’s jet fuel with Bio-SAF, we’d need to use all of our energy crops and agricultural wastes to make it. And that biomass supply is also needed for other things.

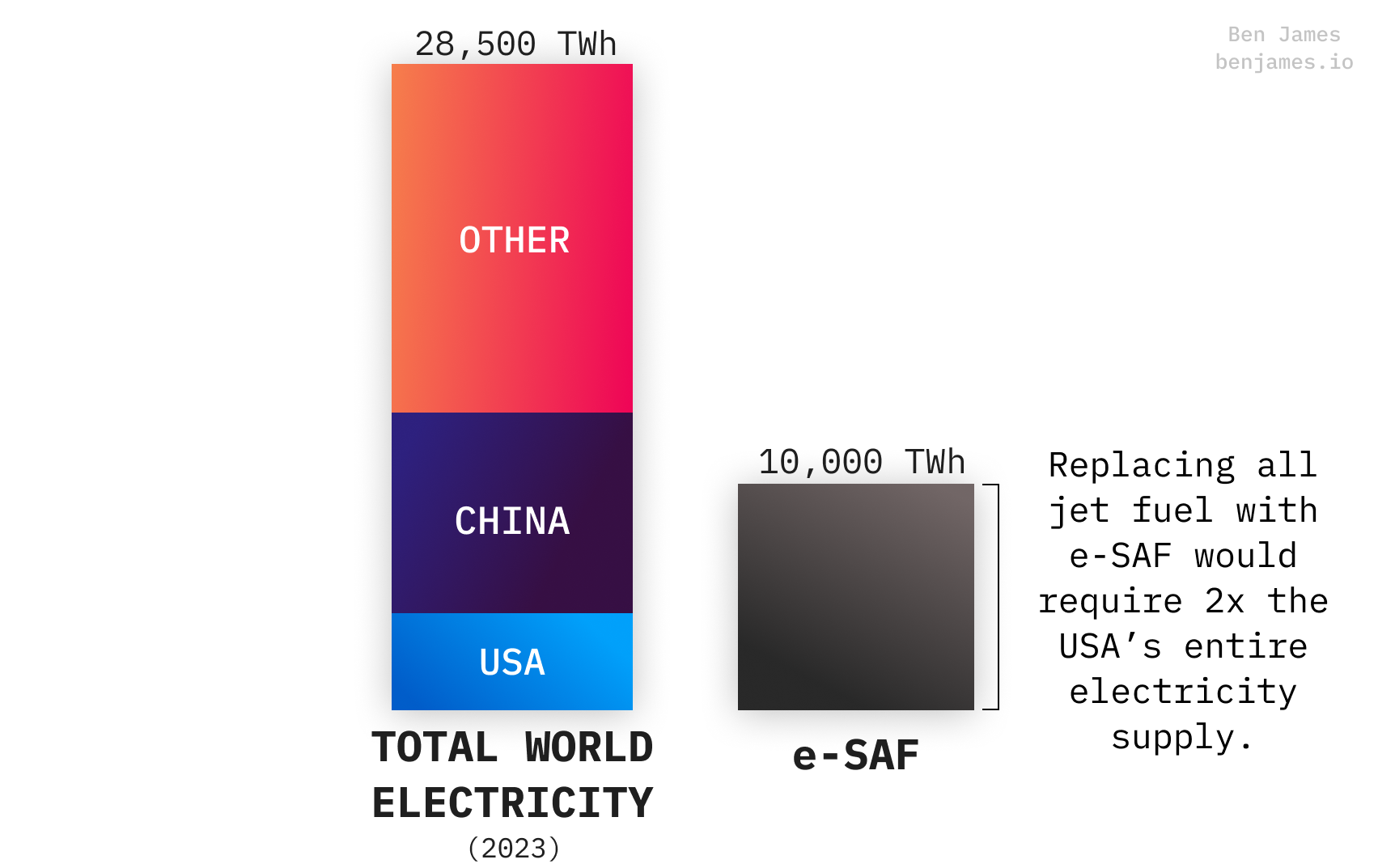

Energy supply:

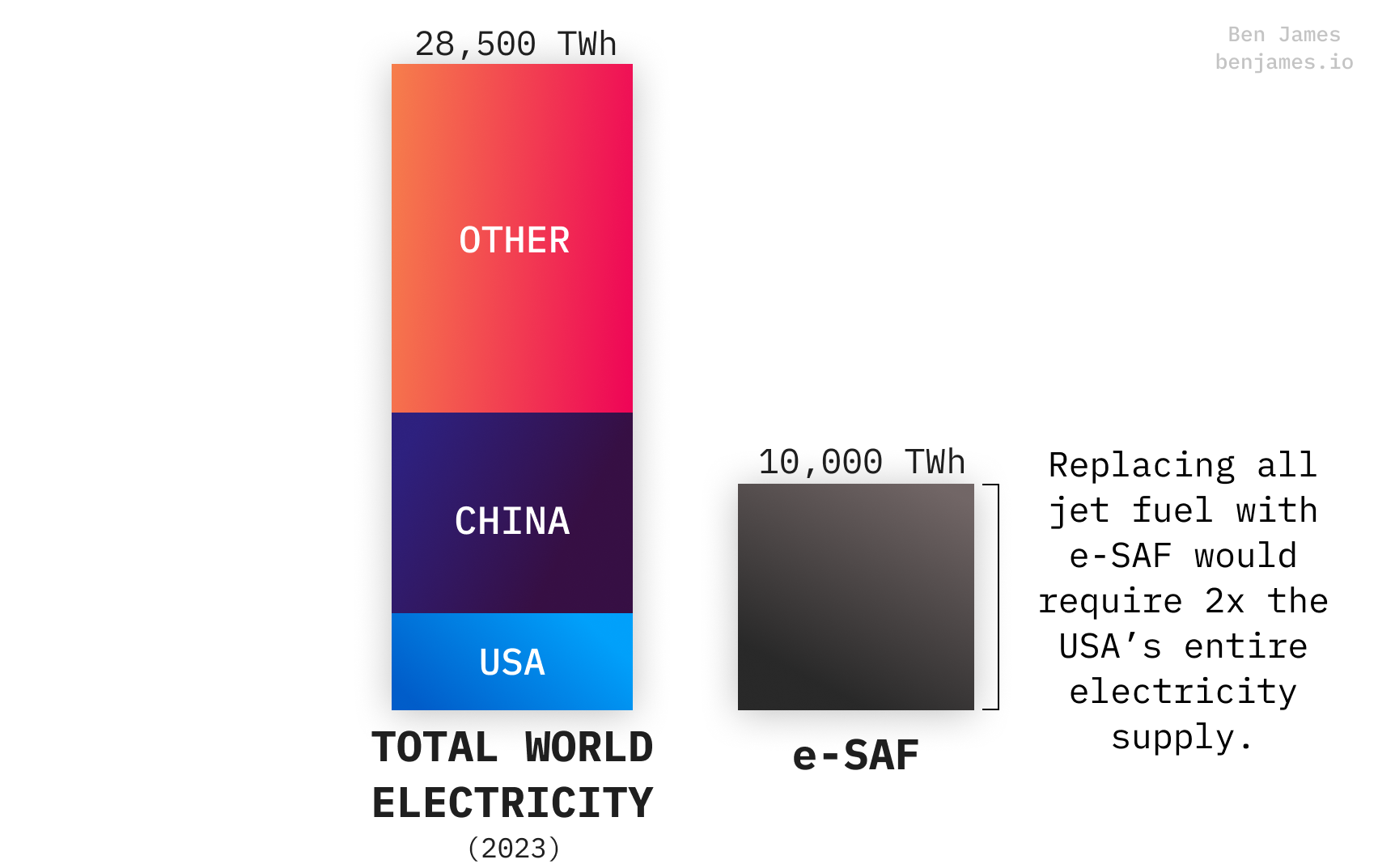

Making e-SAF requires an extraordinarily large amount of energy. It’s like if your mum was an amount of energy.

If we replaced all of today’s jet fuel with e-SAF, we’d need the entire energy supply of a global superpower.

To be clear: e-SAF only works if there is a wartime deployment of clean electricity generation, obliterating any speed of energy infrastructure deployment the west has seen over the past couple of decades.

Without that, SAF displaces green electricity from better climate solutions like electrification, which save more CO2 per kWh. That is greenwashing, and it is extremely cringe.

Meet the pathways

There are numerous ways to produce SAF. Here are the main production pathways:

We’re going to walk through each method one by one. First: Bio-SAF.

Bio-SAF

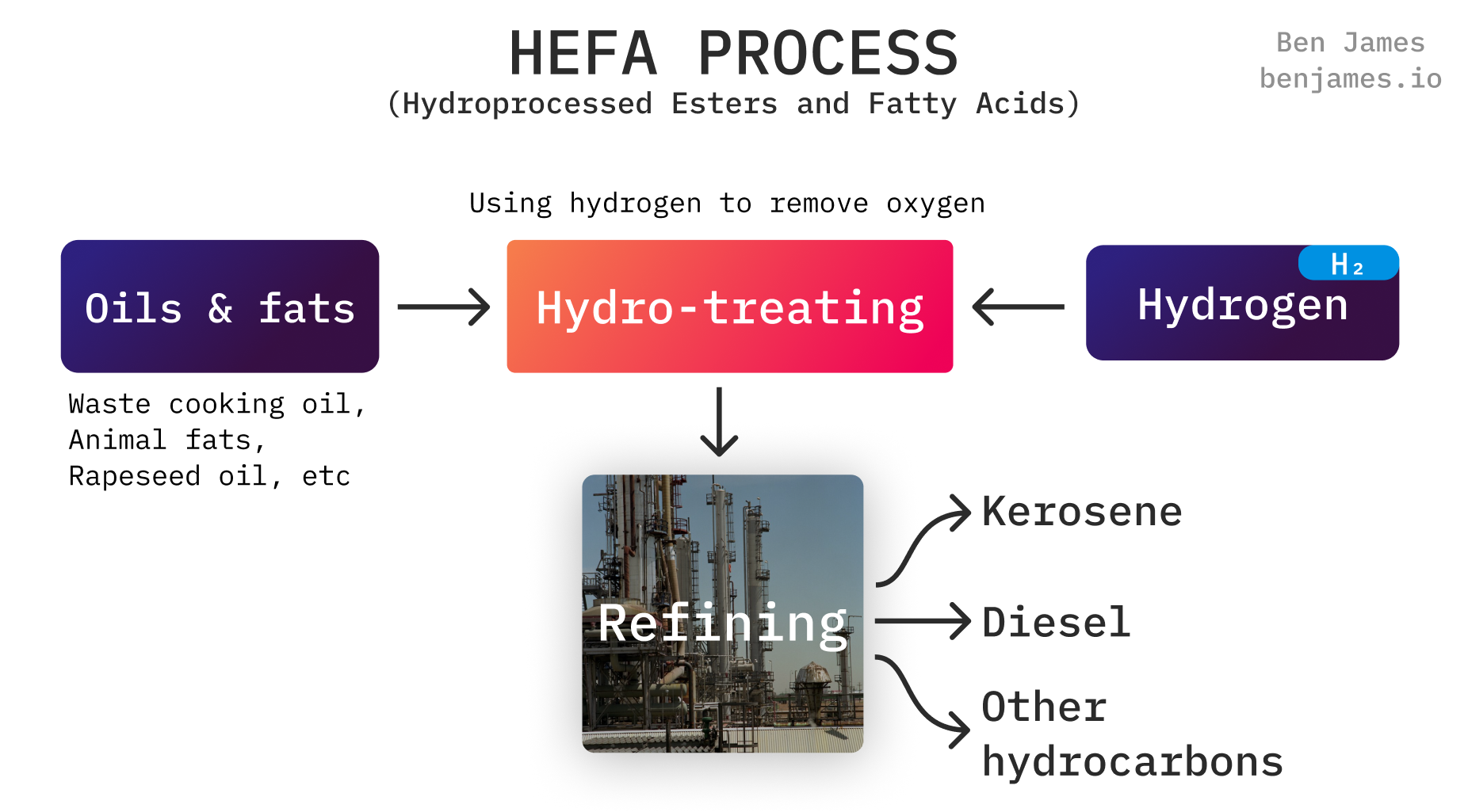

Most Bio-SAF today is made using the HEFA process. HEFA takes waste cooking oil and turns it into fuels like kerosene and diesel.

Ngl that’s kinda epic? We literally collect used oil from McDonalds fryers, cart it over to refineries, then turn it into SAF.

The critical inputs to the HEFA process are oils/fats, and hydrogen. Yes, bio-SAF needs hydrogen too!

HEFA uses traditional refining and chemical engineering processes, so it’s well suited to oil companies and existing refineries.

The problem with HEFA

Unfortunately, HEFA has a mahoosive problem: we don’t have enough waste cooking oil or waste fats.

In Europe, we import 80% of our waste cooking oil from abroad. Most of it comes from China, who will soon start using that oil to make its own SAF, leaving little for export.

What about growing new oil?

Instead of relying on waste cooking oil, what if we grew new vegetable oil just for SAF?

This is a non-starter. To produce enough rapeseed oil to fuel all UK aviation, we’d need to dedicate 68% of the UK’s agricultural land to growing it.

A solar panel converts roughly 10x the energy of a plant, from the same amount of sunlight.

If you used the same area of land to (1) make e-SAF with solar, or (2) make Bio-SAF with crops, the solar option would produce 7x the amount of SAF.

We should either (A) use land for growing food, and use any waste biomass to make SAF, or (B) use land for solar, and make e-SAF.

Fortunately, HEFA is not the only way to make Bio-SAF.

Alcohol-to-Jet

Alcohol-to-Jet is a newer pathway for making Bio-SAF, as well as a British stag party tradition. It's a simple idea:

- Make alcohols (for example, ethanol) from plants.

- Turn your ethanol into SAF.

There are two big advantages of Alcohol-to-Jet over HEFA.

#1. Alcohol-to-Jet can use more types of biomass. Anything that can be converted into an alcohol (which is most plants, if you try hard enough) can make SAF.

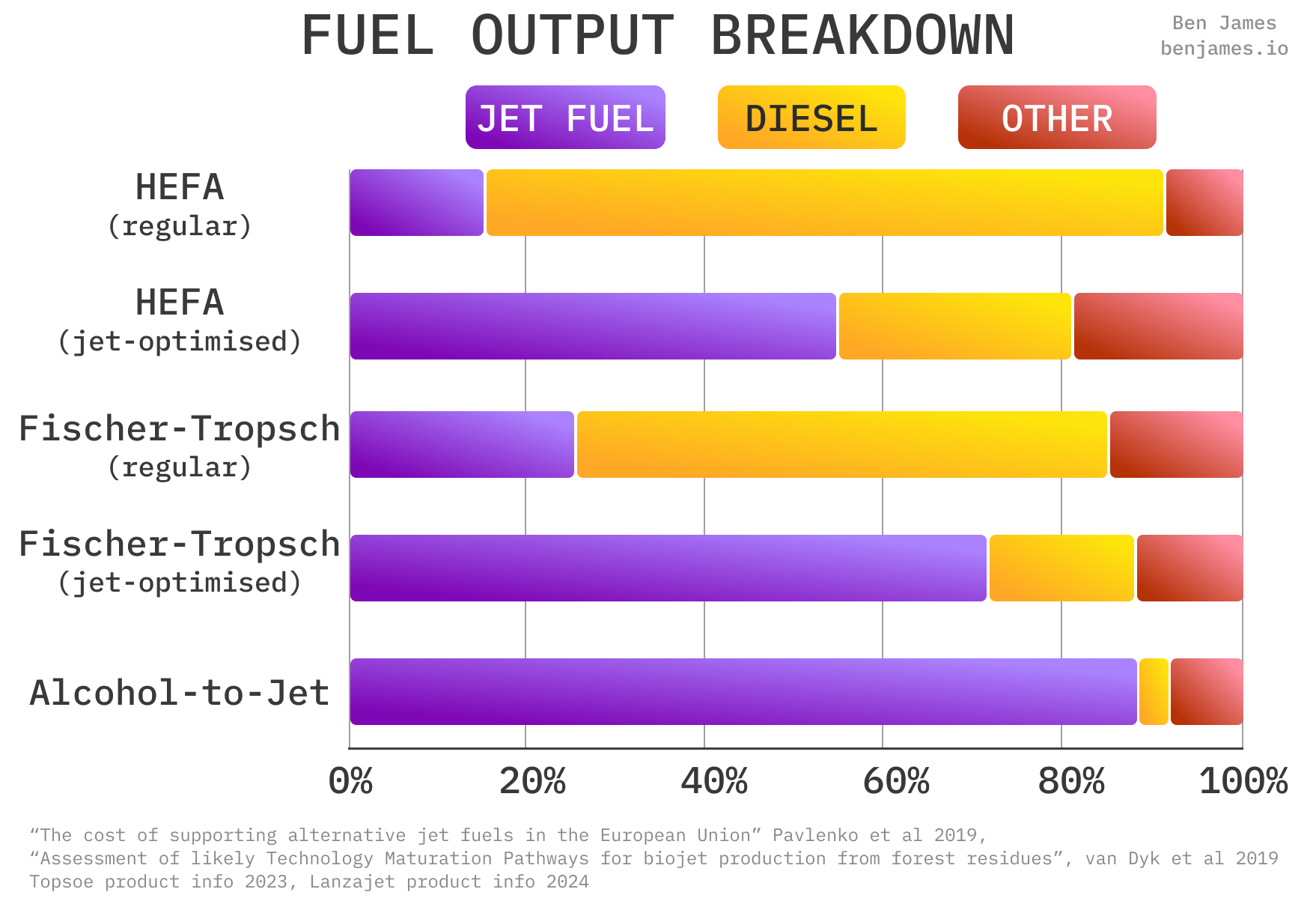

#2. Alcohol-to-jet can be set up to produce a high proportion of jet fuel, with very few other by-products. In the business, this is called having a high kerosene selectivity, and it's important to understand.

All SAF pathways produce a range of hydrocarbons. SAF production with high selectivity will produce chains that are mostly of the right length for jet fuel.

Um, sorry to ask, but where are you getting your ethanol from? 🥰

Most ethanol is made in the US, and in the US, more than 95% of ethanol comes from virgin energy crops. That's not good - dedicated energy crops compete with food production.

However, ethanol optimists will point out:

- There's a lot of unused agricultural waste, like corn stalks and husks, that we can turn into ethanol. This is called cellulosic ethanol, and doesn’t compete with food production. The problem: making cellulosic ethanol is expensive, and everyone who tried it eventually shut down.

- The US makes a lot of ethanol today, and it mostly goes into cars, but soon those cars will be electrified. Surplus ethanol...?

Alright - let’s move on to our second type of SAF!

e-SAF

e-SAF is pretty magical when you stop for thunkin’. We use air, water, and energy to produce jet fuel on demand.

It sounds like science fiction, but it’s entirely possible. The reason that we don’t make e-SAF commercially today is that it uses so much goddamn energy.

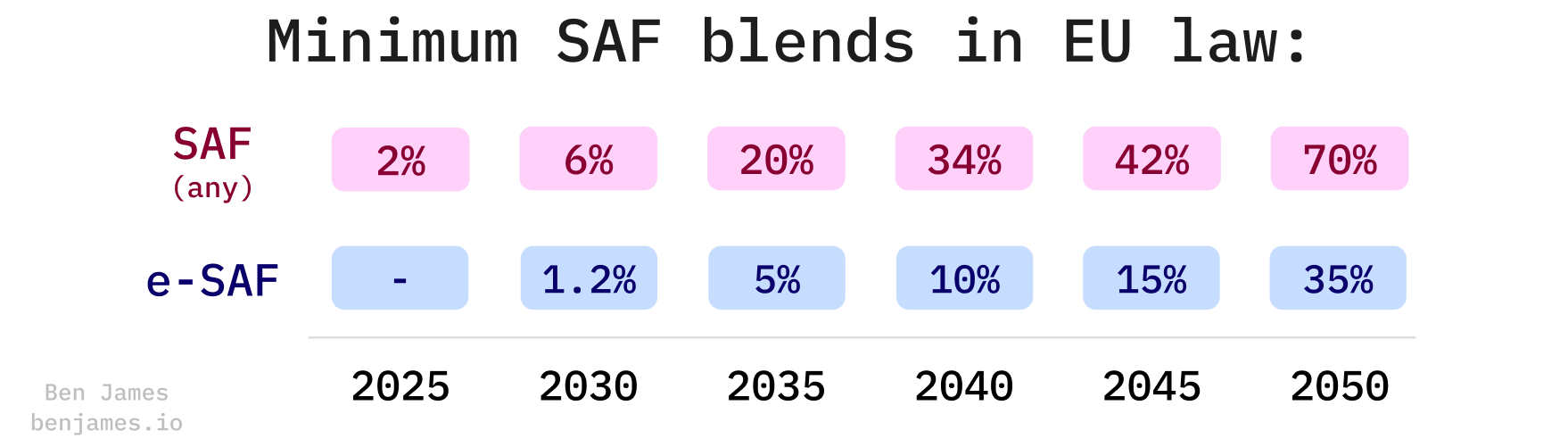

e-SAF is literally the law.

Policymakers realise that planes powered entirely by biofuels would be a disaster for land use and food production. So in addition to mandating minimum blends of SAF in jet fuel, they are mandating minimum blends of e-SAF too.

The Fischer-Tropsch process

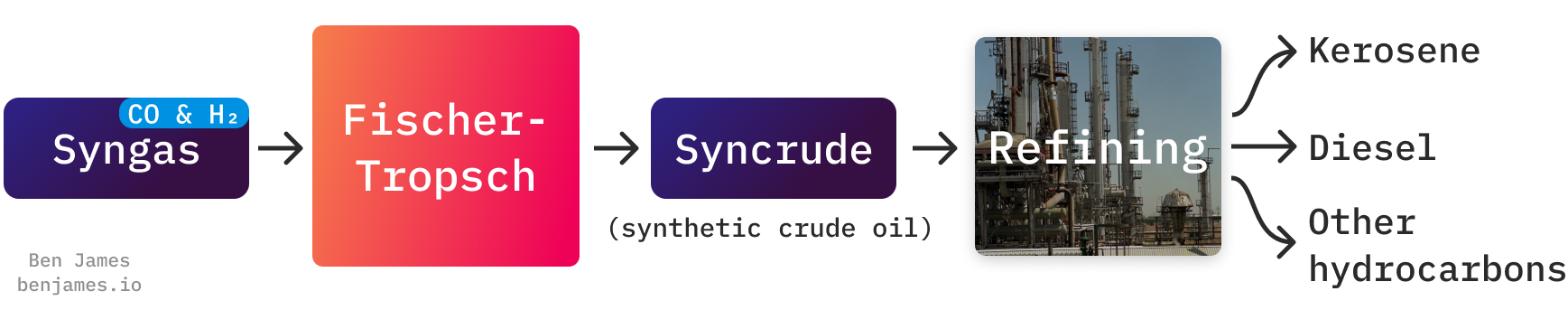

The most mature way to make e-SAF is the Fischer-Tropsch process.

Fischer-Tropsch has been around for ages, but not because of climate change.

Shell’s Pearl GTL plant in Qatar uses Fischer-Tropsch to make liquid fuels from natural gas. It’s one of the biggest energy projects ever, and produces ~10% of Shell’s liquid fuels output from cheap natural gas in Qatar.

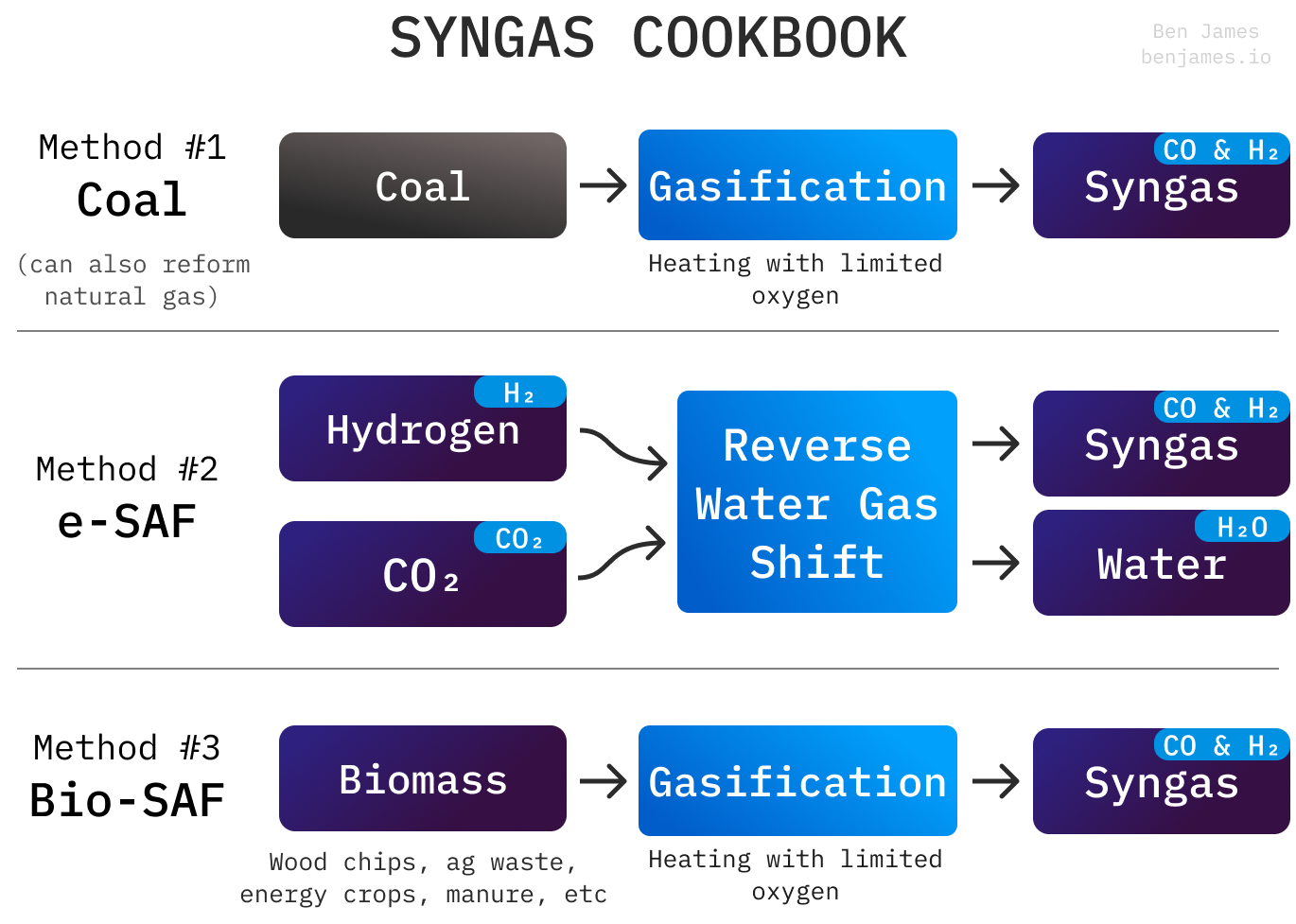

Fischer-Tropsch works by making artificial crude oil from something called syngas.

Syngas

Syngas is made of hydrogen and carbon monoxide.

Traditionally it was produced from coal (cringe) or gas (cringe). For SAF, we can make syngas from hydrogen and CO2. We do this with the Reverse Water Gas Shift reaction, which incredibly is not part of a car, but a nifty way to re-shuffle hydrogen and carbon atoms.

Alright, let's look at some numbers.

Ingredient-economics of e-SAF.

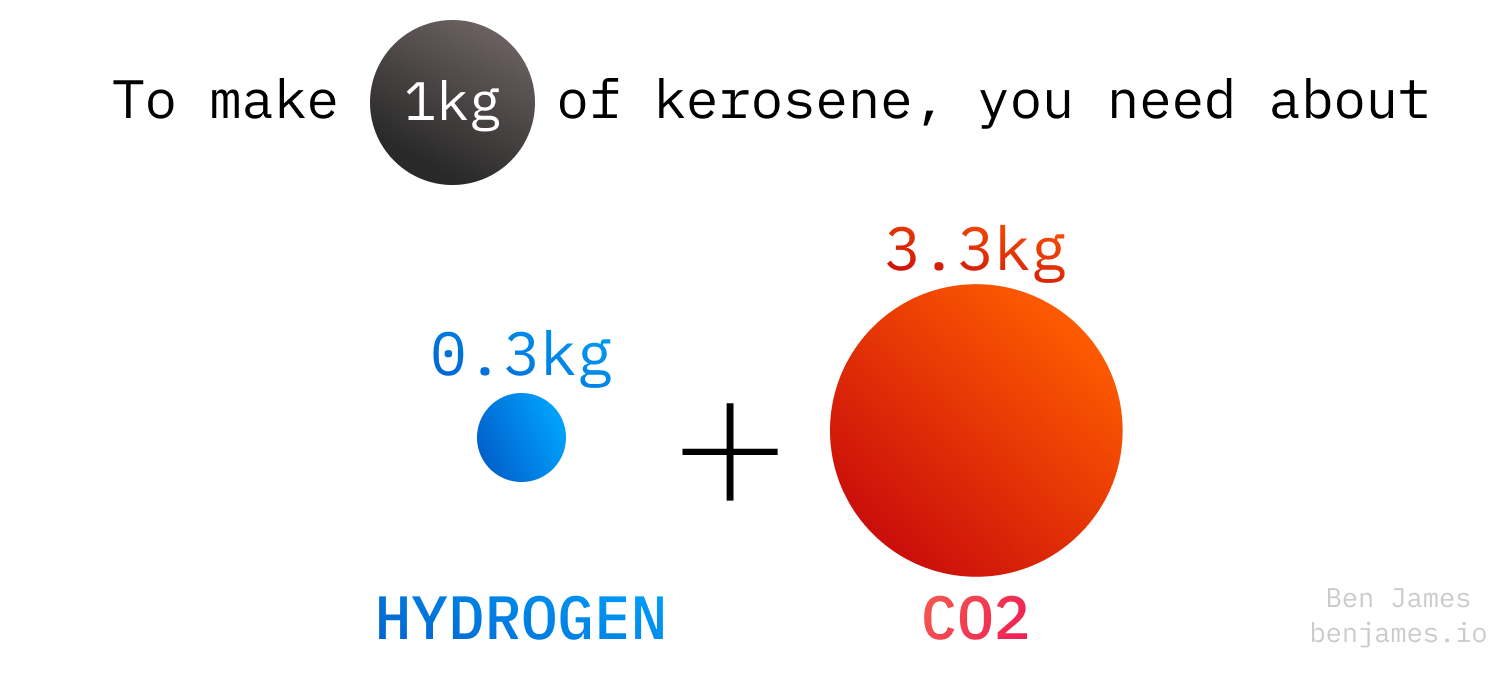

You only need two ingredients to make e-SAF: hydrogen and CO2.

But making hydrogen and capturing CO2 both need extraordinary amounts of energy.

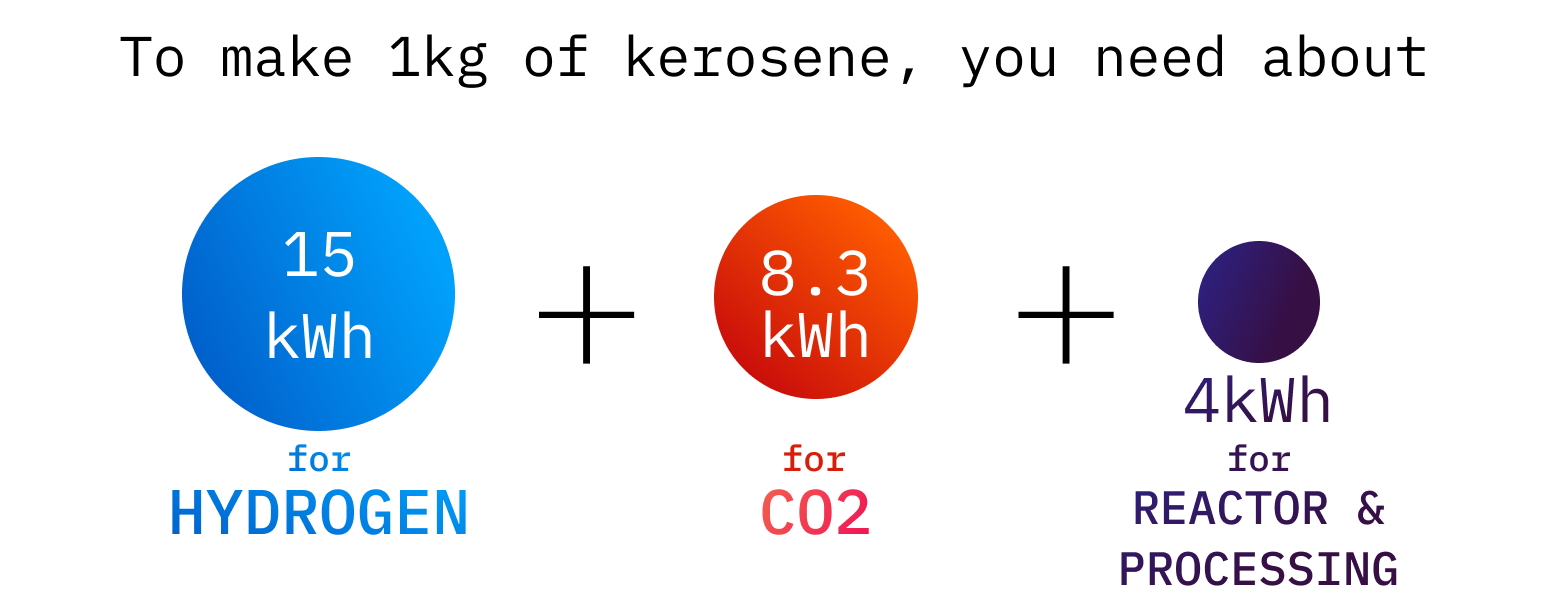

You need about 50 kWh to make a kilo of green hydrogen, and about 2.5 kWh to capture a kilo of CO2 from the air. (I wrote about the energy requirements of hydrogen here, and the energy requirements of Direct Air Capture here)

That means,

Let’s be clear, this is a lot of energy.

It totals out around 100 kWh per gallon of SAF, and we use around 100 billion gallons of jet fuel per year. If we were to replace all jet fuel with e-SAF, we’d need 10,000 TWh to make it.

Unit costs

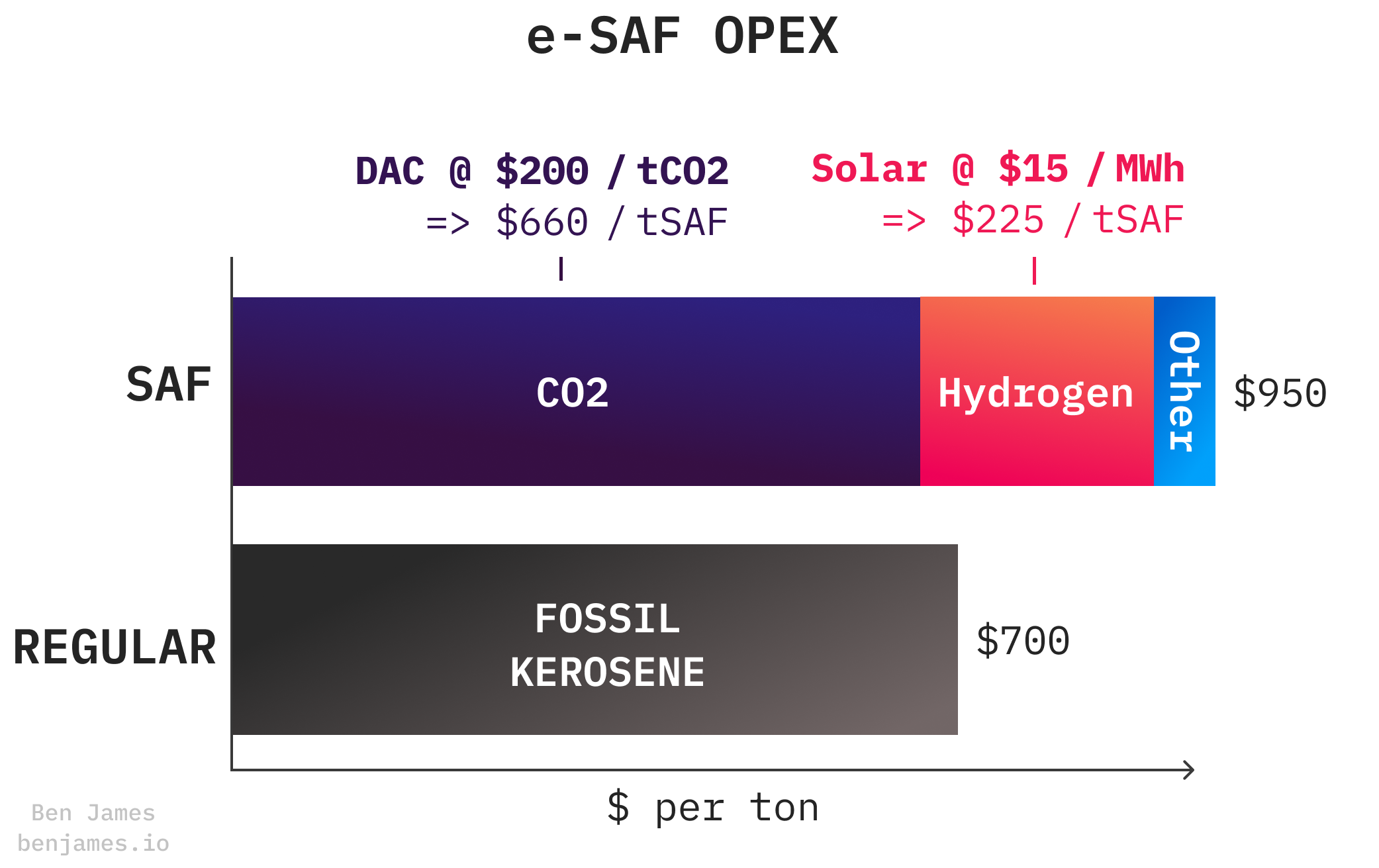

Let’s break down the operating costs of making these e-SAF ingredients.

Let's say that we can pull CO2 out of the sky for $200 / ton, and build solar for $15 / MWh.

I’ll cover how we can minimise the cost of SAF in the “what’s exciting” section below.

Methanol-to-Jet

Methanol-to-Jet is a newer pathway that is a contender to Fischer-Tropsch. It needs the same ingredients as Fischer-Tropsch (CO2 and hydrogen), so the ingredient-economics that we covered above still apply here.

It has a few subtle advantages, which I'll leave as an optional dropdown:

Methanol-to-Jet explained

Methanol is an alcohol, so it can go through the Alcohol-to-Jet process we covered above.

However, the official ASTM standard for Alcohol-to-Jet does not allow methanol to be used in SAF. That means that it can’t currently be certified as jet fuel, although this will likely change in the next couple of years.

The main advantage of Fischer-Tropsch is its maturity - we know that it can work at scale.

But there are two small advantages that methanol-to-jet offers over Fischer-Tropsch.

#1 - High selectivity

Just like ethanol-to-jet, methanol-to-jet’s killer feature is its high selectivity. It can eek out a little more jet fuel for the same energy input.

#2 - Decentralised production

Methanol can be made in many different regions, then shipped to a central refinery to be converted into SAF. If the best places to build off-grid renewables are remote, this could be convenient.

Methanol can be made from electricity or biomass - I wrote a guide to how methanol is made here.

Methanol-to-Jet costs

The inputs to e-methanol and Fischer Tropsch are identical: hydrogen and CO2. It’s just that methanol-to-jet rearranges them temporarily before they become kerosene.

That means that the ingredient-economics of Fischer-Tropsch and methanol e-SAF are very similar, and the cost analysis above still holds. Methanol will convert a slightly higher proportion into kerosene, so the numbers will look slightly better after accounting for the varied product basket.

Which SAF technologies are exciting?

The answer to this question is actually very simple.

SAF is bottlenecked by the availability of biomass and cheap energy. Therefore,

For e-SAF, that means abundant, off-grid, energy.

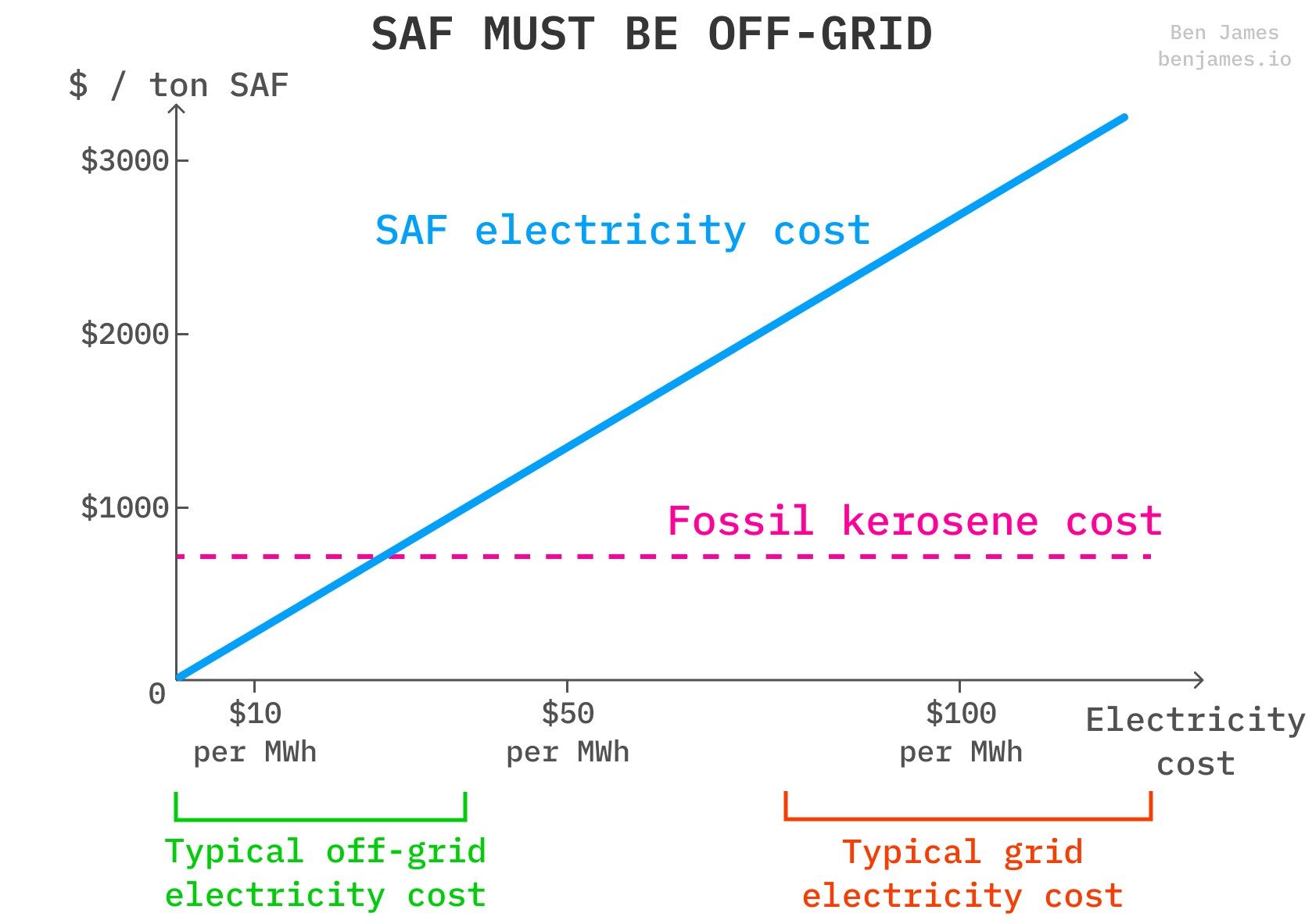

One thing is clear: using electricity from the grid to make e-SAF is too expensive.

Additionally,

- If you’re taking electricity from the grid to make SAF, you’re probably stealing electricity from more potent ways to reduce emissions (ie, electrification).

- The necessary grid upgrades would be ludicrous. We’re talking about taking the entire energy consumption of dragging humans through the sky, and forcing it to pass through pylons beforehand. Pylons that are already under strain, and extraordinarily costly and slow to build.

Cool, so we’ll build off-grid solar just for SAF, or use SAF to mop up excess power when the grid is ‘full’. That’s great, but it means we can only run our SAF plant 20-40% of the time. Synfuels plants are expensive, so it sucks to have them dormant 70% of the day.

Thus, the critical advancements to make e-SAF are:

- Build cheap, abundant, off-grid renewables (already on track)

- Make synfuels plants really really cheap - even at the expense of efficiency.

For Bio-SAF, we need abundant biomass.

The good news is that we have plenty of plants that grow very fast, like seaweed and bamboo.

The bad news is that growing them from scratch and converting them to SAF is expensive and requires using the land or ocean (& oceans require permits). Nonetheless, I’ve yet to see a good reason why we can’t grow new biomass in a much cheaper and automated way.

It's worth noting that in the past decade, most oil majors took a swing at growing algae for biofuels, but all their programmes ran into difficulties and eventually shut down.

I’m still optimistic, because our recent advancements in biotech are astounding. We have capabilities today that we could only dream of in 2010. Whether it’s cheap cellulase enzymes that make cellulosic ethanol economical, or simply plants-that-grow-fast, we should not ignore the potential of biotech to help us out here.

Conclusions

SAF is the only realistic way to decarbonise long-haul flying, and producing it is entirely possible.

But without abundant energy or biomass, making SAF will actively increase emissions. It will steal energy or land from more effective climate solutions.

The question "will SAF work?" is just a wrapper for the question "how fast do you believe we can build things?". Can we hurl our infrastructure into the future fast enough to catch ourselves?

To bet on SAF is to bet on bold & targeted energy policy, a revival of industrial dynamism, and the fastest buildout of energy infrastructure in living memory.

Would you take that bet? I'll leave you to decide.

Thanks!

Thanks to Finlay Asher, Dusita de Hoop, Valentin Batteiger and Oliver Booth for their time / help with this piece. Opinions and mistakes in this piece are entirely mine, not theirs.

Footnotes

Footnote 1

SAF has less aromatics, but we could also make fossil kerosene have less aromatics too! Hydrotreating fuels to mop up aromatics and nasties is common practice, and we already do it to reduce sulphur in diesel. Some hydrotreated kerosene is already produced.

Read more here - thanks Finlay.

Footnote 2

Two things to note here:

1. Today, the price of diesel is often higher than kerosene, so plants optimise for making diesel. This is bad, because we need clean jet fuel much more than clean diesel. Diesel is much easier to replace with electrification.

2. You can make more SAF in all of of these pathways by post-processing your output. You can crack long hydrocarbon chains down to the right size - it just requires more energy.